At GSM, we’ve written a few articles on the various methods of binding. In this article we look specifically at the craft of case binding…

Case binding is the method of binding ‘hardback’ books or documents. Unlike ‘softback’ binding methods, such as Perfect / PUR / Burst or saddle stitching, Case binding involves a significant amount of manual work. This extra work reflects the higher cost of this binding method. There are, however, many advantages with Case binding over the softback methods. Hardback documents can often be opened flat—which is not possible with a large Perfect / PUR or Burst bound document. Case binding is also significantly more durable, and has a higher perceived value.

Case binding is the method of binding ‘hardback’ books or documents. Unlike ‘softback’ binding methods, such as Perfect / PUR / Burst or saddle stitching, Case binding involves a significant amount of manual work. This extra work reflects the higher cost of this binding method. There are, however, many advantages with Case binding over the softback methods. Hardback documents can often be opened flat—which is not possible with a large Perfect / PUR or Burst bound document. Case binding is also significantly more durable, and has a higher perceived value.

Trimming, Collating & Stitching

Case binding is done by Bookbinders at a bindery. As a general rule, the cover and internal pages usually arrive pre-printed and untrimmed from a printery. The bindery begins by cutting down the oversize folios (oversized sheets that contain multiple imposed pages) into four-page sets.

Case binding is done by Bookbinders at a bindery. As a general rule, the cover and internal pages usually arrive pre-printed and untrimmed from a printery. The bindery begins by cutting down the oversize folios (oversized sheets that contain multiple imposed pages) into four-page sets.

They then collate these sets (groups of corresponding readers pages) and stitch them together at the binding edge with cotton.

Glueing

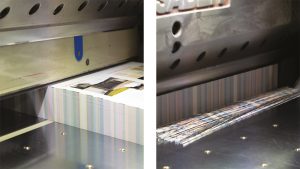

A case bound document comprises a number of stitched sections which the binder glues together in the correct reading order forming all the internal pages.

They then glue the endpapers onto the outside front and outside back page and trim the finished group to the correct size.

Cover Construction

The next stage is to construct the cover which is largely done by hand. This involves cutting the backing card to the correct size.

The next stage is to construct the cover which is largely done by hand. This involves cutting the backing card to the correct size.

then trimming and laminating the printed covers.

then trimming and laminating the printed covers.

The backing card (one for both the front and back cover) are glued to the reverse side of the printed cover  .

.

Once the operator glues a card spine in place they can stick the cover wrap-around edges down.

Finally, they press the cover through a roller and the internal pages can be inserted.

Assembly

The internal pages are secured to the cover via the endpapers—which are glued to the inside front & inside back cover. You can see in the images how the binder glues the internal stitched sections and the black endpapers together. On most case bound books, we do not glue the bind on the internal pages to the inside spine on the cover— the resulting space and flexibility allows the book to open flat.

The internal pages are secured to the cover via the endpapers—which are glued to the inside front & inside back cover. You can see in the images how the binder glues the internal stitched sections and the black endpapers together. On most case bound books, we do not glue the bind on the internal pages to the inside spine on the cover— the resulting space and flexibility allows the book to open flat.

The completed books are then pressed until the glue dries.

The completed books are then pressed until the glue dries.

Job done.

GSM would like to extend our thanks to the team at McHargs Bookbinders (Christchurch) for assisting us with this article. Cheers team!

Photos by Xavier Murphy @xalacreative